Day 11 - Closing up the box

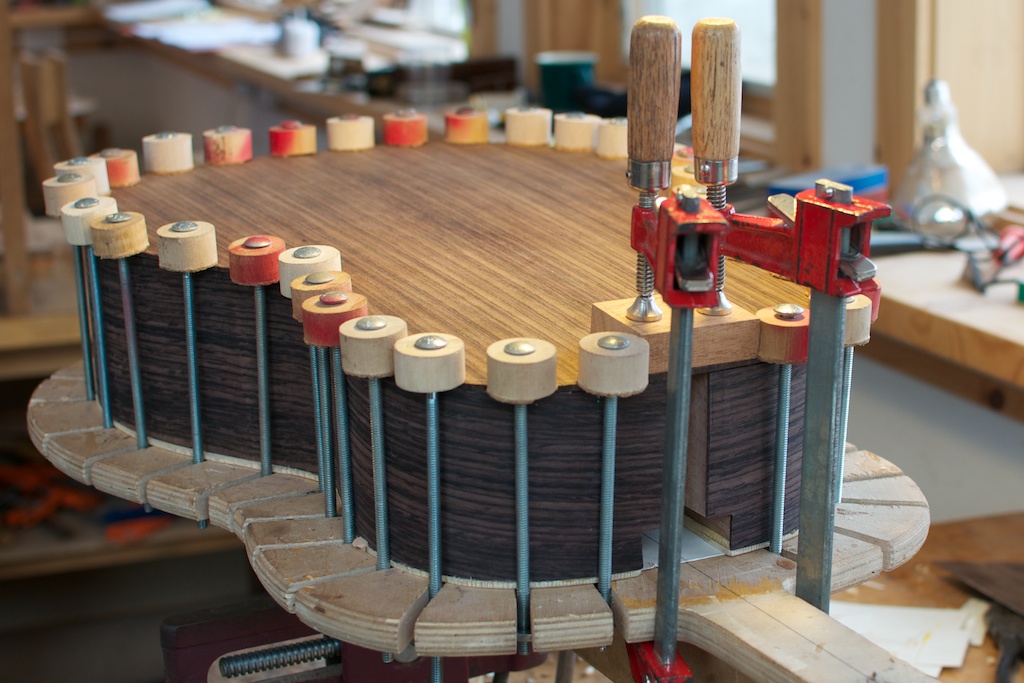

Day 11: Yesterday we got the sides ready to attach to the back; today we started the day getting the back ready to take the sides by trimming up the bracing on the back to fit within the sides. Then we glued on the back; we now have a fully enclosed guitar body!

While I waited for the glue to dry in the body, I finished up cutting my headstock inlay. I’m really happy about how it turned out (note, it’s much, much smaller than it looks in this picture...closer to the size of two dimes). This is only about 4 hours of work :-)

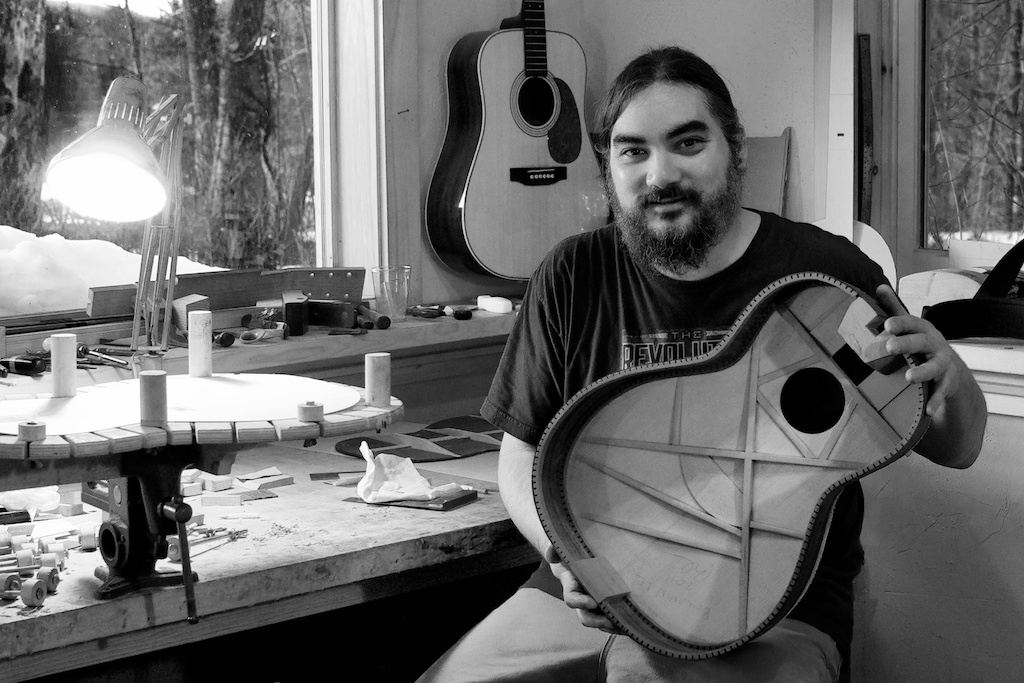

Once the body came out of the clamps, we checked the fit of the neck. In general, the fit of the neck to the body is the thing I’m most anxious about. So far, so good; fingers crossed.

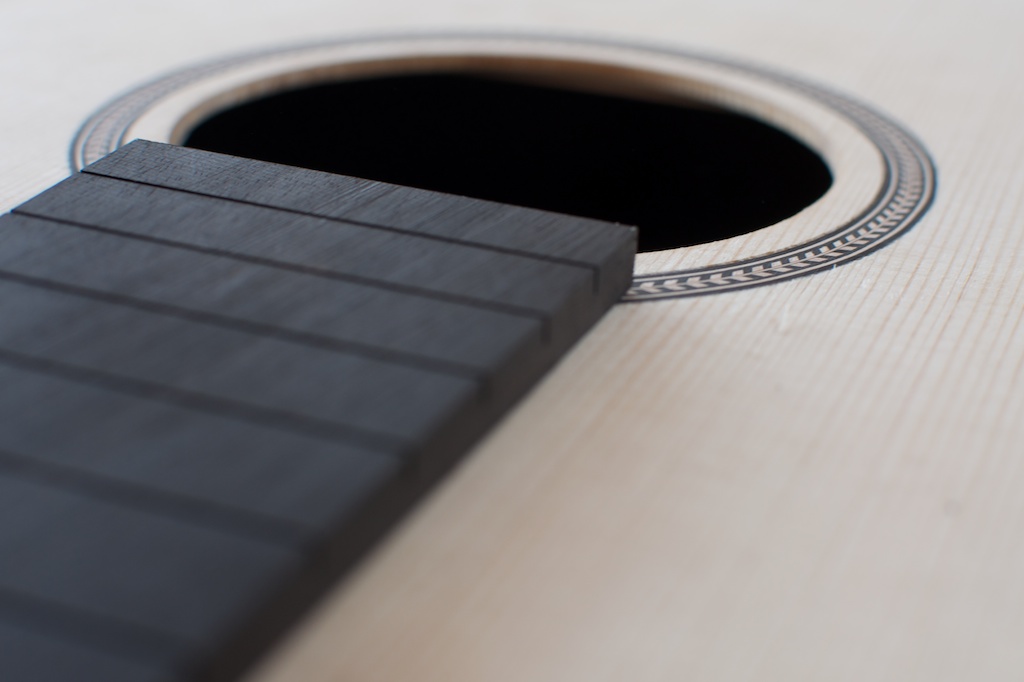

We also began working on the fretboard; a very clever and handy template helped us cut the slots for the frets. My guitar will have 18 frets, although that’s more than twice as many as I typically need! We also cut the shape of the fretboard (edges/length); this was actually easier than I anticipated using the bandsaw for the rough cut and joiner to get the edges straight.

Started at 8:00am, finished at 6:30pm, with an hour for lunch.

Thursday, March 31, 2011

Thursday, March 31, 2011