What every jam needs - David Cavins Tenor Guitar #19

A couple of years ago I reconnected with my college friend and luthier David Cavins, who is based in Columbia, Missouri. David builds beautiful guitars, and although I'm pretty much flush with 6-string acoustics, his tenor guitars piqued my interest. In particular, I wanted to expand my sonic palette while also challenge myself with new tunings beyond 6-string guitar, banjo, and the other instruments I've been fortunate to find across the years. I have a mandolin and although I'm a proficient rhythm player, playing breaks never quite clicked for me. I figured a tenor guitar would give me a comfortable way (as a guitar player) to get more familiar with mandolin-family tunings, while also adding some diversity to our weekly jams (so many guitar and banjo players!). So at the end of last year David started designing a tenor guitar for me.

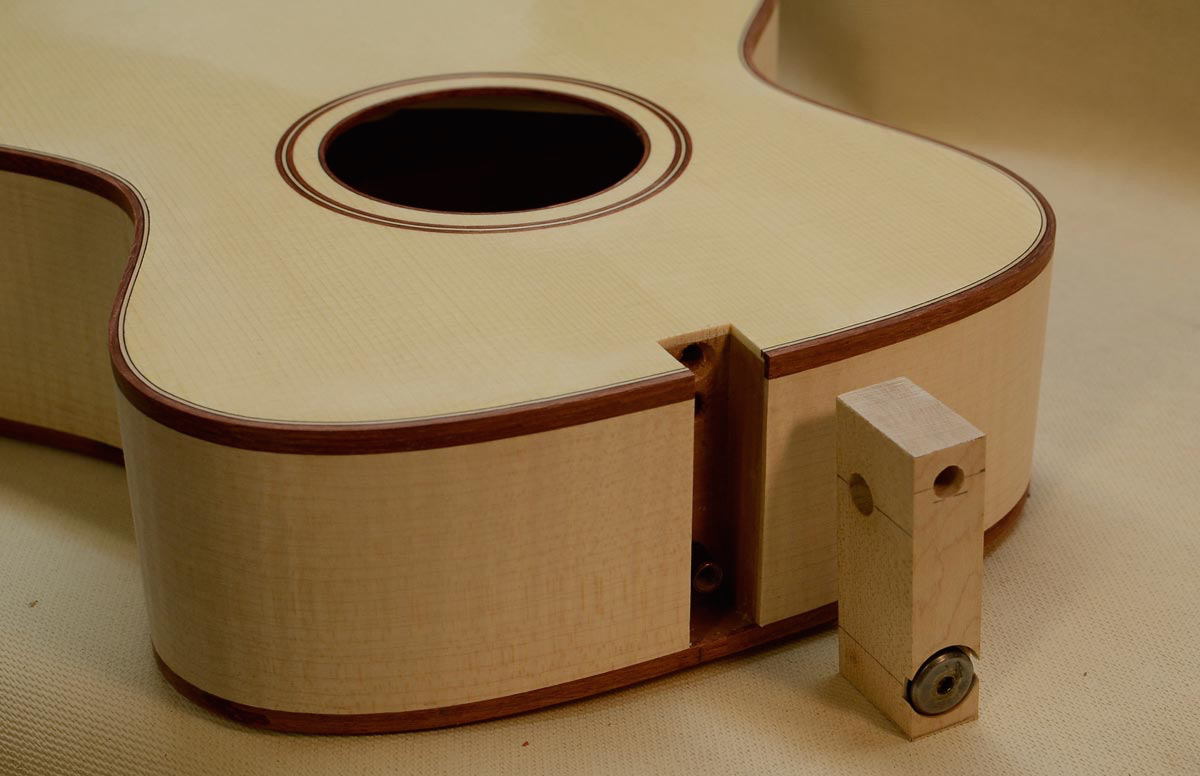

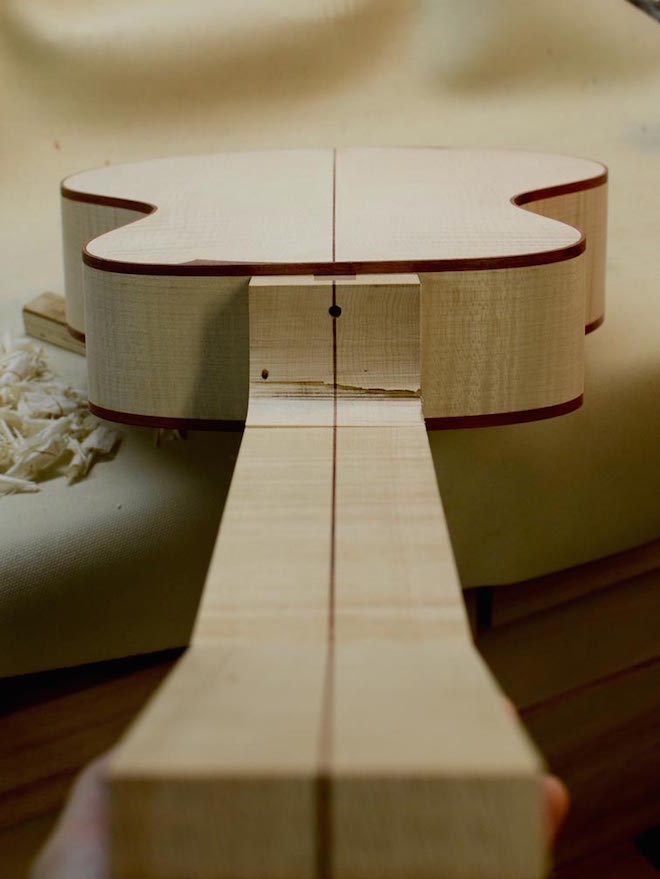

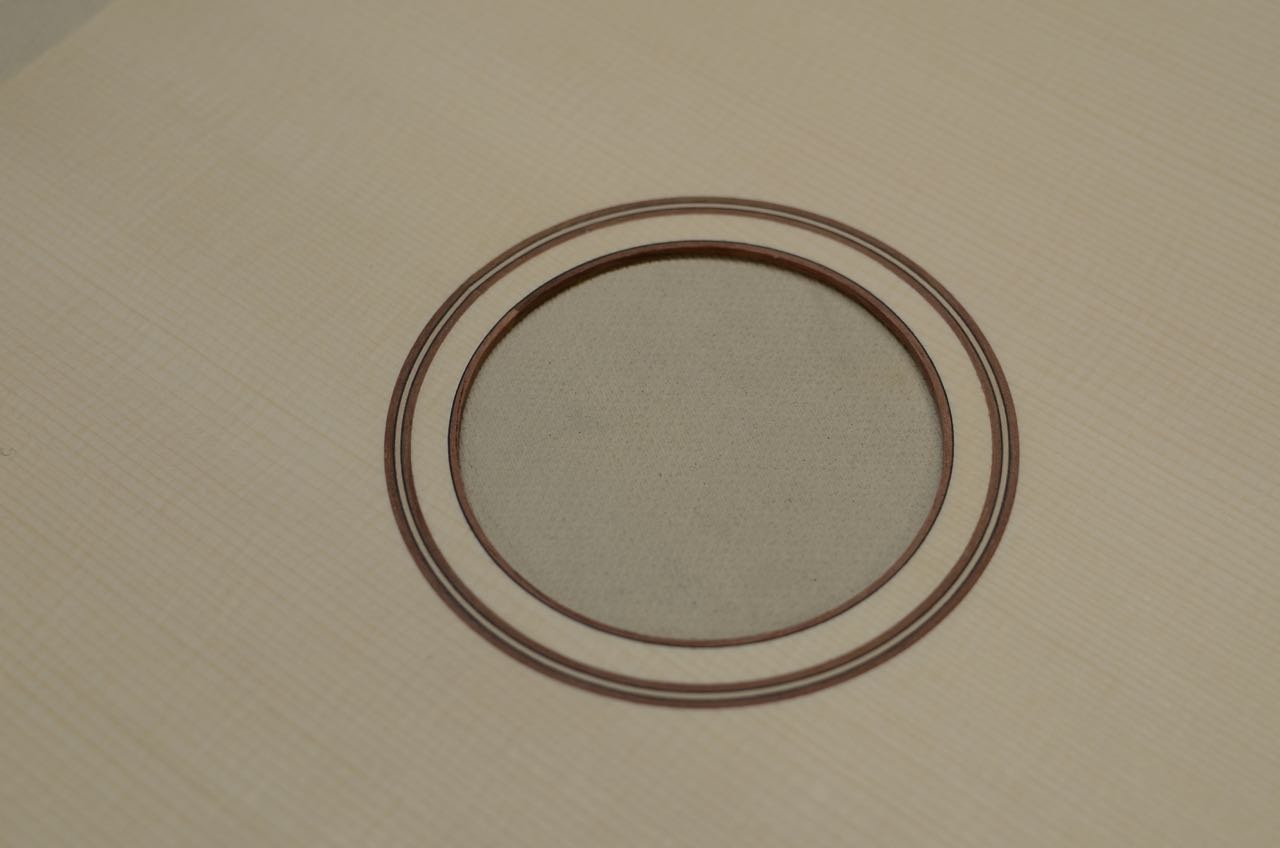

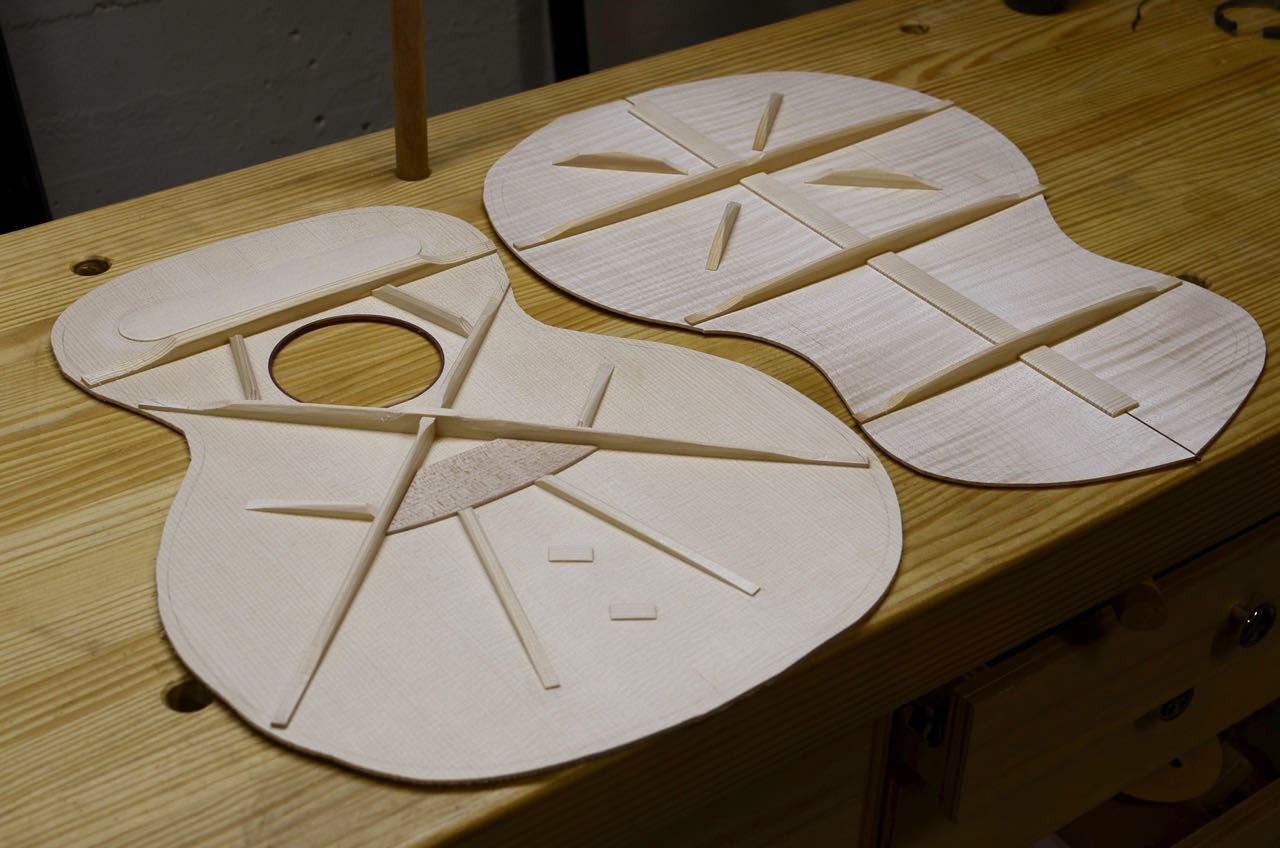

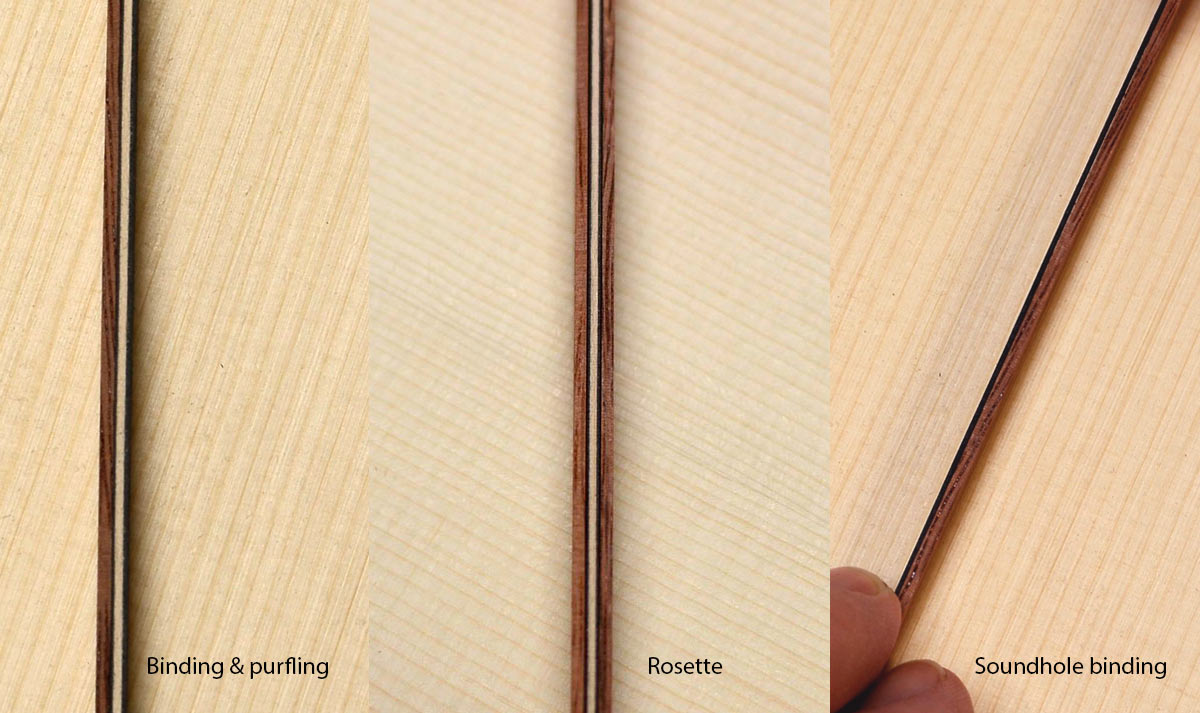

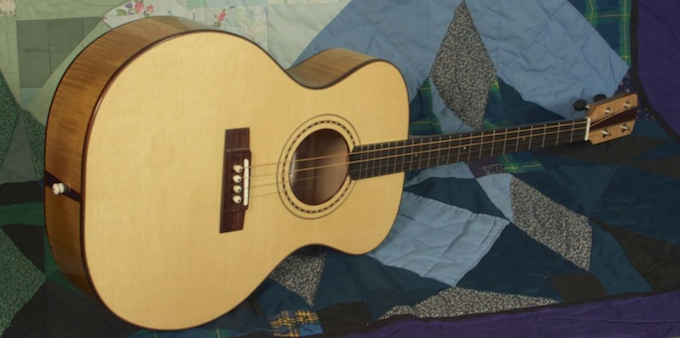

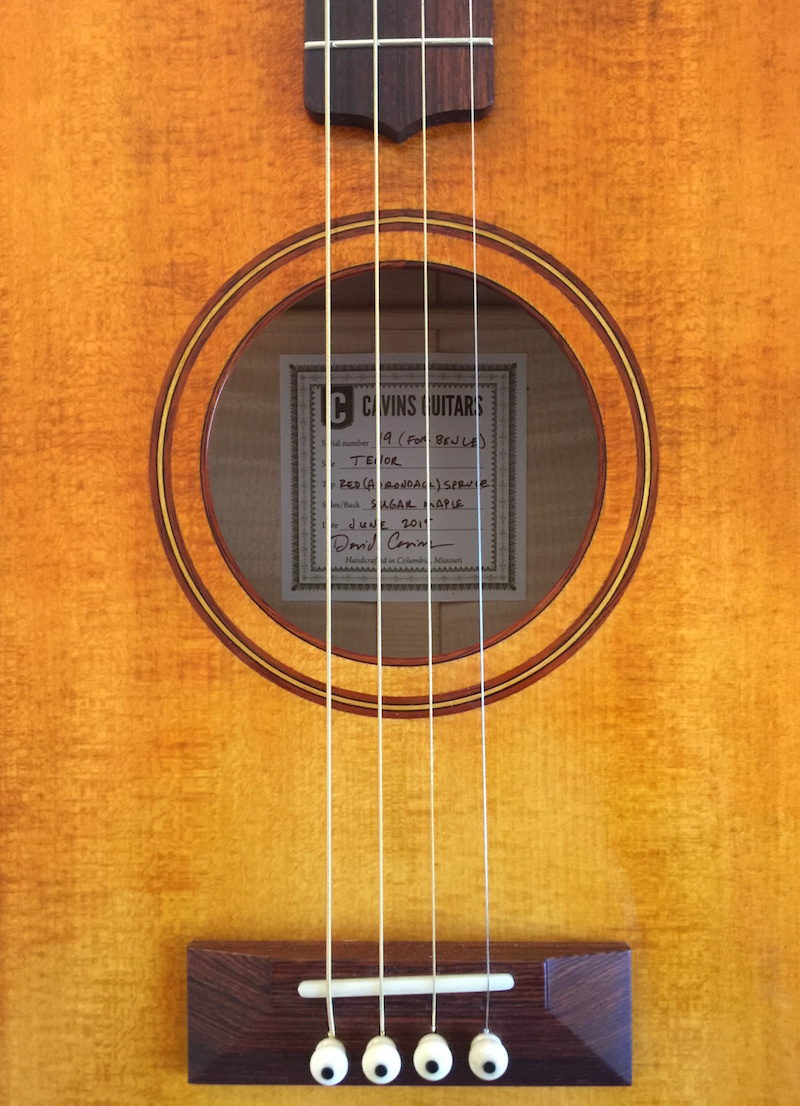

I previously have posted about the design and build process (see the series of six posts here: 1, 2, 3, 4, 5, and 6), which includes lots of pictures that David send me along the way. Essentially, we each blogged the process in parallel from our perspectives. To briefly review, David's tenors are inspired by a Gibson TG-0 rather than the Martin 0-18T popularized by the Kingston Trio. My guitar is 13" across the lower bout and 3.688" in depth at the endpin, with a scale length of 22.875" and nut width of 1.25". We settled on flamed sugar maple for the back, sides, and neck, with an adirondack spruce top. The binding and other decorative bits are primarily hormigo, and the fretboard and bridge are Honduran rosewood. This guitar has a couple of other unique features, including two subtle "wave " inlays around the perimeter of the back, the strikingly brilliant sunburst shading under the French polished finish, and David's newly-designed adjustable neck joint (see more details about the neck on David's site at the bottom of this page and mid-way down this page).

I received the tenor from David last week and am absolutely blown away by its beauty, and more importantly, by the tone of this instrument. Describing a guitar's tonal qualities is always difficult, especially when I haven't actually played any other tenors and thus don't have a reference point. So I'll just simply say that I can't imagine a tenor sounding any better than this one! At some point I'll try to get around to posting some sound clips, but for now you'll just have to enjoy these pictures.

A couple things I've learned from this process:

1) Working with a luthier on a custom built guitar is a very fun and satisfying experience.

2) David is an extremely talented craftsman, artist, and musician, in addition to being just about the nicest guy you'll ever meet (although I've know this last point since we first met in 1994). If you're looking for a tenor guitar, or auditorium, orchestra, or concert-sized guitar, working with David can't be beat. The balance of tradition, innovation, and responsible choices of sustainable materials in his instruments hits the spot for me, and the design of my tenor guitar is executed into a beautiful sounding, looking, and feeling instrument.

Saturday, December 19, 2015

Saturday, December 19, 2015