Day 5 - My new best friend = the "go bar deck"

Day 5: Today might have been the most interesting day so far. I’ve been looking forward to doing the bracing of the top, and today we got to beginning doing that. From the pictures and description, it might not sound like a lot was accomplished but it was actually a really busy day.

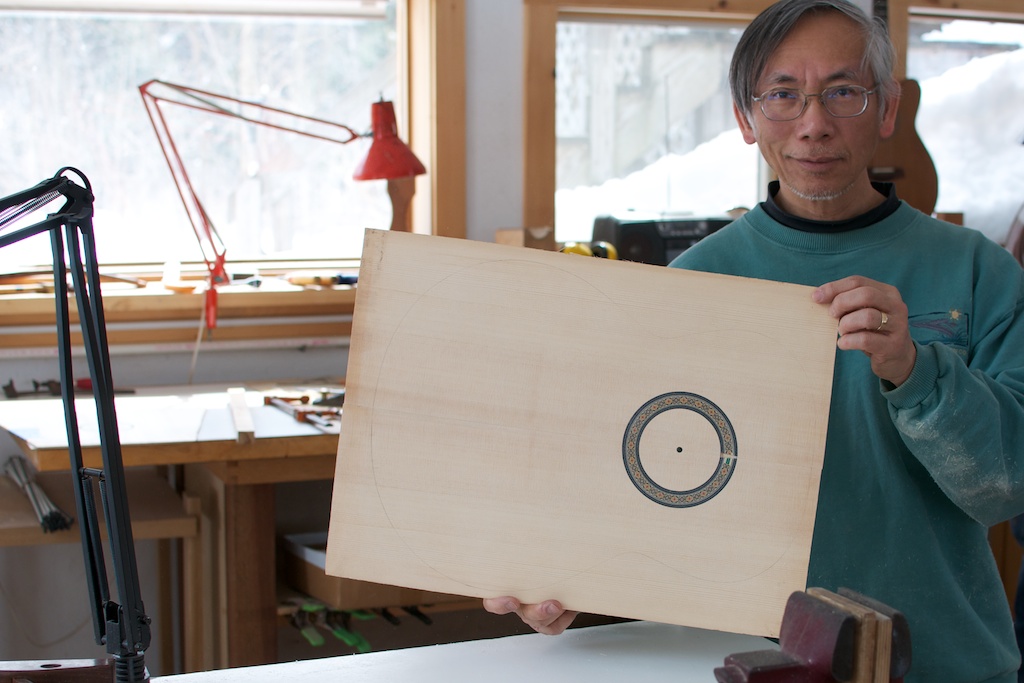

The bracing for the top and back is made with small pieces of very stiff spruce (mostly; the back has one piece of cedar in the design we’re using). The back is radiused, meaning you put a slight arch into it in both directions, so each brace must be carefully shaped to include that curve, so that when they are glued to the back it will be pulled into that radius.

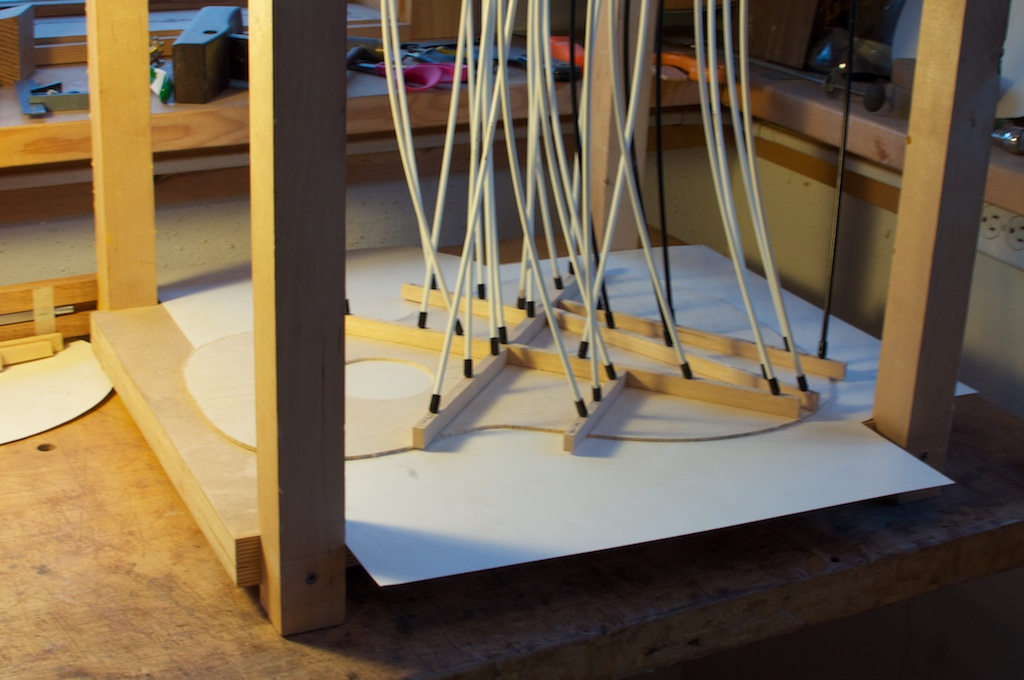

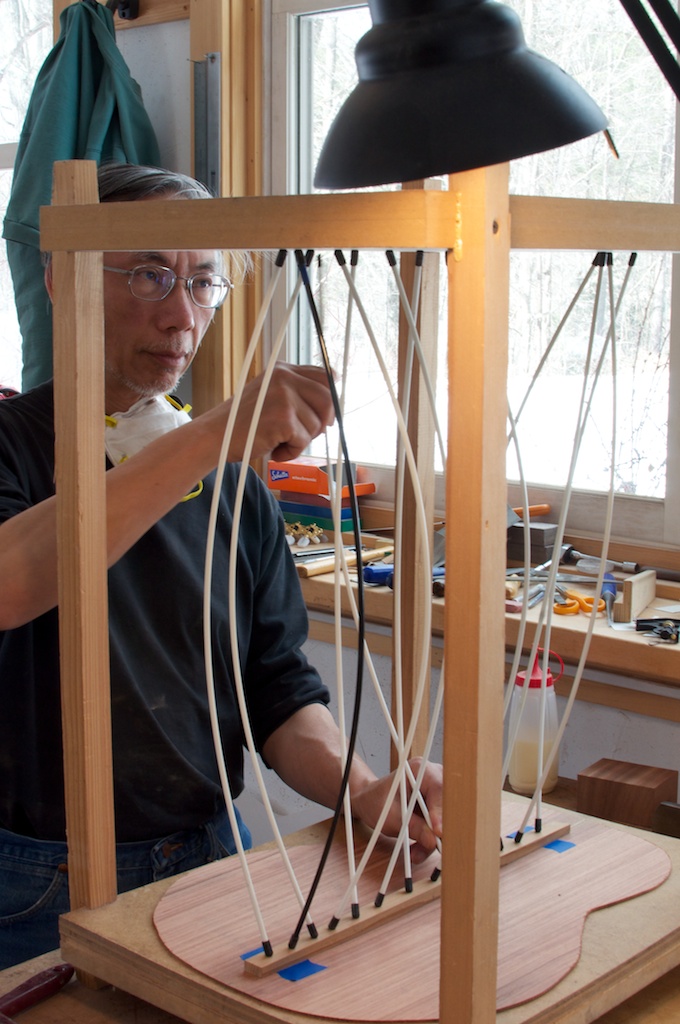

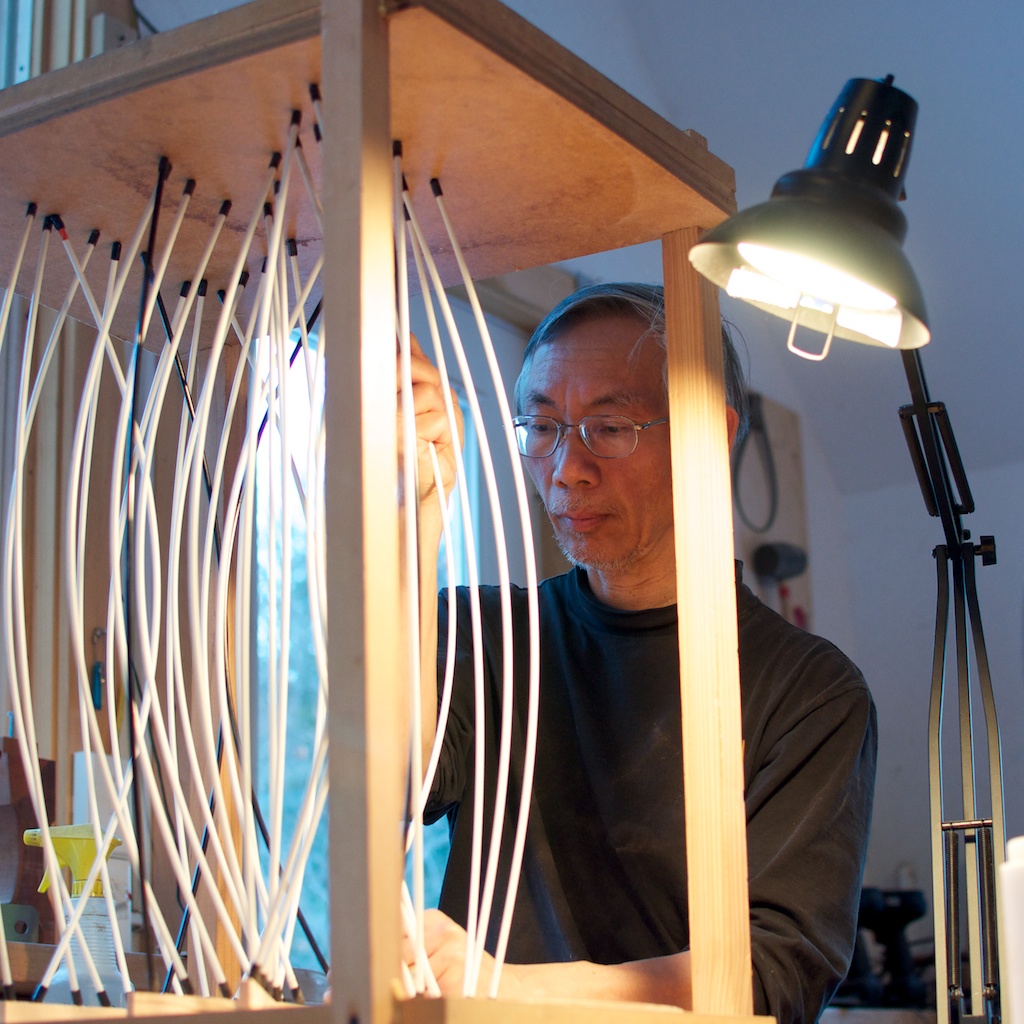

The center back brace was glued into place with the “go bar deck,” which is a frame with a floor and ceiling (one is flat and the other is radiused), just smaller in height than a series of fiberglass sticks (made from the same material as kite poles). Right now it’s a bit oversized; we'll shave that down later and then install three braces that intersect with this brace and run the width of the back.

In addition to beginning to brace the back, we also did the bracing on the top. Most of us (at least those building steel string guitars) used a variation of the traditional Martin X-bracing system. Thanks to my iPad, I was able to quickly able to bring up a picture of the interior of a prewar Martin similar to the design I’m building, so I copied that as best I could. The bracing for the top was also glued on using the go bar deck, and in the next few days we’ll begin shaping the bracing.

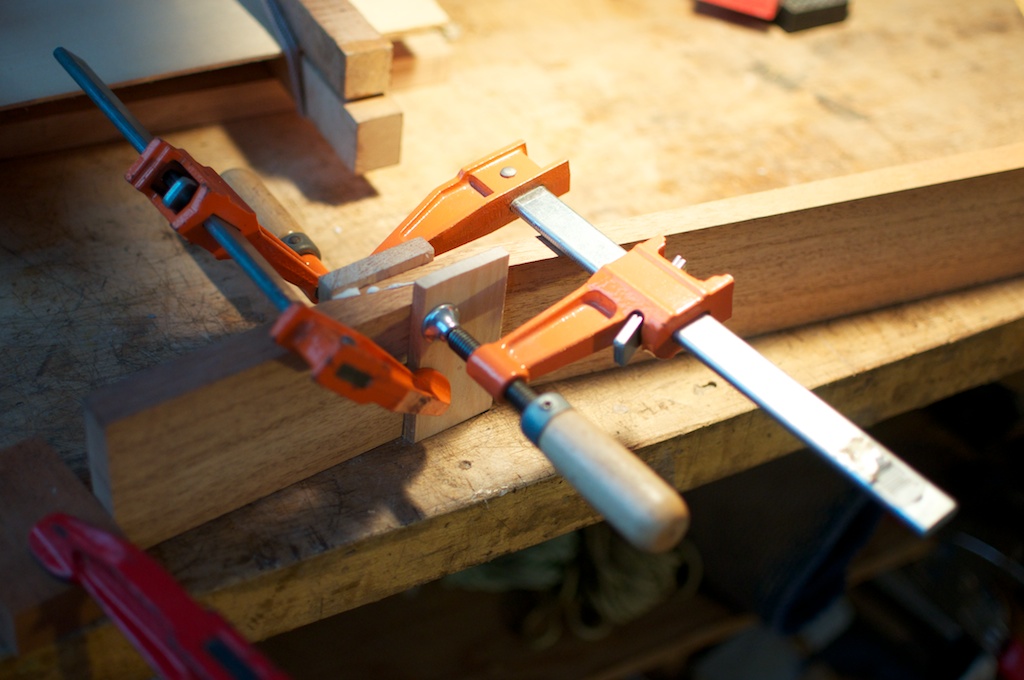

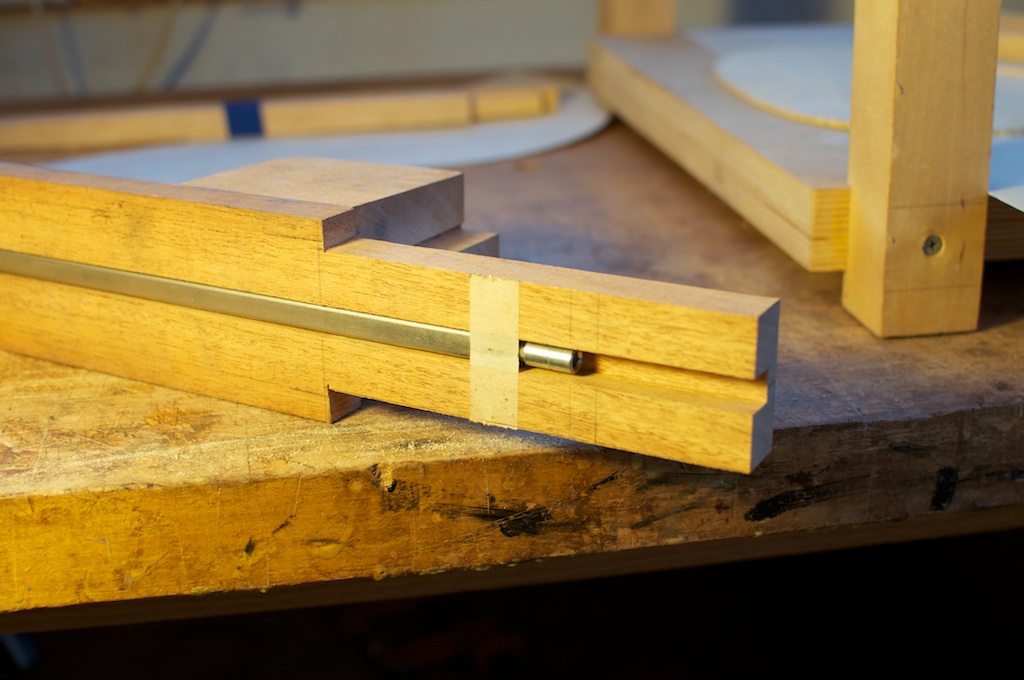

In between glueing bracing to the back and top, we continued doing some work on the neck, this time trimming down the “tongue” that will be inserted into the body. Anytime you take a bandsaw to the neck it’s traumatic, but with some careful measuring (“measure twice, cut once” evolved into “measure five times, cut once” for some of us) it all ended up okay.

In the shop by 8am, home at 6:45 or so (although the last 45 minutes or so a few of us hung out chatting while others finished up the day’s tasks). Looking forward to bending sides and binding tomorrow!

Friday, March 25, 2011

Friday, March 25, 2011